Stations

PS-DC Models

PS-DC Models

Manufacturing units qualified for the Pack&Strat® process allowing the manufacture of 3D packaging in various materials (cardboard, single, double and triple corrugated cardboard, polyethylene foam, …) based on a digital cutter machine whose characteristics will be adapted according to the detailed needs of the customer:

- Vacuum cutting table

- Many usable areas available: from 1050 x 1500 mm to 2200 x 3200 mm

- Many possible belt configurations: fixed or conveyor

- Suction power: between 2 kW and 9 kW depending on the table size chosen

- Various beam heights: maximum working thickness from 25 mm to 120 mm (depending on the tool)

- Automatic cutting initialization device

(fast, easy and reliable configuration of the cutting depth) - Basic configuration with 2 tool holders equipped with:

- 1 electric oscillating knife module

- 1 grooving module

- Pen marking module

- Other tools available:

- Micro-milling spindle (see PS-DC-MF models)

- Universal tangential cutter

- Pneumatic oscillating cutter

- Variable pressure tangential cutting (Kiss- Cut)

- Bevel cutting (V-Cut)

- Notching and punching modules

- 1 PC with keyboard/screen and control software

- 1 license of Pack& Strat®

- 1 license of the Pack& Strat®(unlimited duration on one station)

- Expansions possible to multiple stations

- Transportation, installation, commissioning of the complete station on site

- Training in the use of the Pack& Strat®(manufacturing unit and software)

- Telephone support (hotline) in the use of the Pack&Strat® process and provision of Pack&Strat® software updates (annual subscription)

Models PS-DC-MF

Models PS-DC-MF

Manufacturing units qualified for the Pack&Strat® process allowing the manufacture of 3D packaging in various materials (cardboard, corrugated cardboard, honeycomb cardboard, polypropylene, polyethylene foams, wood plywood, MDF, …) based on a digital cutter and micro-milling machine, the characteristics of which will be adapted according to the detailed needs of the customer:

- Vacuum cutting and machining table

- Many usable areas available: from 1050 x 1500 mm to 2200 x 3200 mm

- Many possible belt configurations: fixed or conveyor

- Suction power: between 2 kW and 9 kW depending on the table size chosen

- Various beam heights: maximum working thickness from 50 mm to 150 mm (depending on the tool)

- Automatic cutting and machining initialization device

(fast, easy and reliable machining depth configuration) - Basic configuration with 3 tool holders equipped with:

- 1 micro-milling spindle

- Various spindle powers available: between 350 W and 8 kW

- 1 electric oscillating knife module

- 1 grooving module

- 1 micro-milling spindle

- Pen marking module

- Other tools available:

- Universal tangential cutter

- Pneumatic oscillating cutter

- Variable pressure tangential cutting (Kiss-Cut)

- Bevel cutting (V-Cut)

- Notching and punching modules

- 1 PC with keyboard/screen and control software

- 1 license of the Pack& Strat®

- 1 license of the Pack& Strat®(unlimited duration on one station)

- Expansions possible to multiple stations

- Transportation, installation, commissioning of the complete station on site

- Training in the use of the Pack& Strat®(manufacturing unit and software)

- Telephone support (hotline) in the use of the Pack&Strat® process and provision of Pack&Strat® software updates (annual subscription)

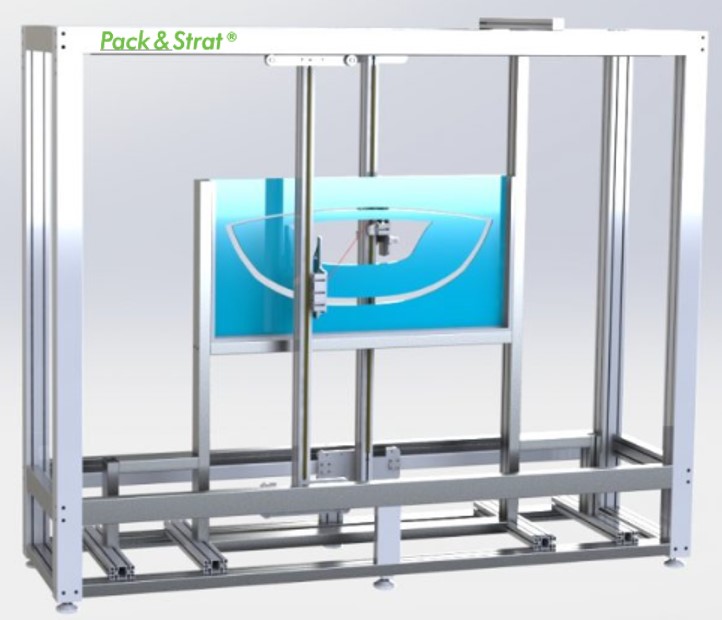

PS-HW Models

PS-HW Models

Qualified manufacturing units for the Pack&Strat® process allowing the manufacture of 3D packaging in various materials (expanded polystyrene, extruded polystyrene, …) based on a digital hot wire cutting machine whose characteristics will be adapted according to the detailed needs of the customer:

- 4-axis hot wire cutting technology

- Many usable areas available: from 1150 x 600 x 115 mm to 5000 x 2500 x 250 mm

- Speed: 3.5 m/min

- Resolution: 0.1 mm - accuracy: ± 1.0 mm - repeatability: 0.05 mm

- Wire diameter: 0.3 mm

- 1 PC with keyboard/screen and control software

- 1 license of Pack&Strat® process

- 1 license of Pack& Strat®(unlimited duration on one station)

- Expansions possible to multiple stations

- Transportation, installation, commissioning of the complete station on site

- Training in the use of the Pack& Strat®(manufacturing unit and software)

- Telephone support (hotline) in the use of the Pack&Strat® process and provision of Pack&Strat® software updates (annual subscription)